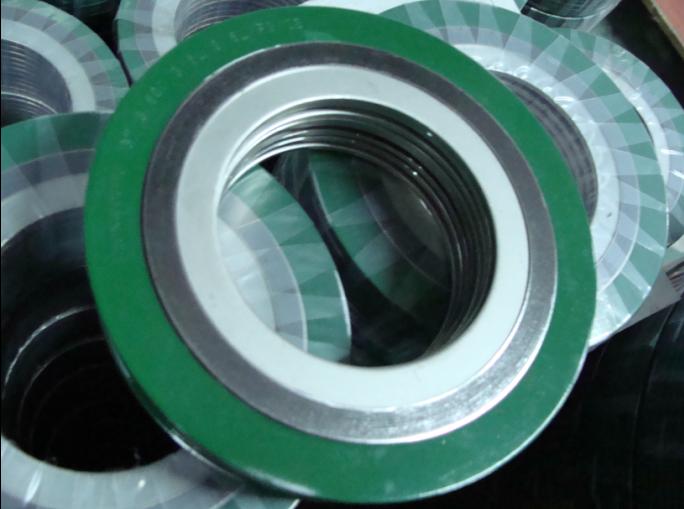

金属缠绕垫

T.C.I Spiral wound gaskets are manufactured from V-shaped (or W shaped) metal strips, spirally wound with an inlay of soft filler (Graphite, PTFE, asbestos etc ) material between each turn. They form a very effective seal when compressed between two flanges.

A V-shaped (or W-shaped) crown centered in the metal strip acts as a spring, giving gaskets greater resiliency under varying conditions. Filler and metal strip material can be changed to accommodate different chemical compatibility requirements.

When spiral winding only (containing preformed metal and soft filler material) is used as a gasket, inner and outer diameters of winding are reinforced with several plies of metal without filler to give them greater stability.

A spiral wound gasket may include a centering ring, an inner ring or both. The outer centering ring centers the gasket within the flange and acts as a compression limiter. The inner ring provides additional radial strength. The inner ring also reduces flange erosion and protects the sealing element.

Spiral wound gaskets are widely used in refineries, chemical processing plants, power generation, and a variety of valve and specialty applications.

Spiral wound gaskets may be used in place of solid metal oval or octagonal API ring joint gaskets when their gasket groove is badly worn out.

Gasket identification markings required by ASME B16.20 are as under.

This spiral wound gasket is identical to the basic type, however an inner ring has been inserted to enhance gasket performance and an external guide ring accurately centers gasket on flange face. The inner ring of spiral wound gasket is added to prevent the possibility of the gasket imploding into the pipe during installation, to protect the sealing element from extreme temperatures and mediums, fill the void between flanges to prevent erosion of the flange, and to reduce the possibility of failure. The inner ring of spiral wound gaskets is normally made of the same alloy as the winding.

The DIN 2699 standard (German) specifies inner rings in all spiral wound gaskets. Inner rings are required for gasket with PTFE filler according to ASME B16.20 standards, and considered important for graphite fillers. This profile is normally used in raised and flat faced flanges. The external ring a provides additional radial strength to prevent gasket blowout and acts as a compression stop. The outer ring is often made of carbon steel (painted or zinc plated to prevent corrosion) but can be made of alloys for higher temperature and more severe medium applications.

These gaskets are generally used for higher temperatures and pressures. A variety of metals are available for the winding strip as well as for the support rings for different temperature application as following for spiral wound gaskets.

| Material |

Minimum |

Maximum |

Abbreviation |

| °F |

°C |

°F |

°C |

| 304 Stainless Steel |

-320 |

-195 |

1,400 |

760 |

304 |

| 316L Stainless Steel |

-150 |

-100 |

1,400 |

760 |

316L |

| 317L Stainless Steel |

-150 |

-100 |

1,400 |

760 |

317L |

| 321 Stainless Steel |

-320 |

-195 |

1,400 |

760 |

321 |

| 347 Stainless Steel |

-320 |

-195 |

1,700 |

925 |

347 |

| Carbon Steel |

-40 |

-40 |

1,000 |

540 |

CRS |

| 20Cb-3 (Alloy 20) |

-300 |

-185 |

1,400 |

760 |

A-20 |

| HASTELLOY® B 2 |

-300 |

-185 |

2,000 |

1,090 |

HAST B |

| HASTELLOY® C 276 |

-300 |

-185 |

2,000 |

1,090 |

HAST C |

| INCOLOY® 800 |

-150 |

-100 |

1,600 |

870 |

IN 800 |

| INCOLOY® 825 |

-150 |

-100 |

1,600 |

870 |

IN 825 |

| INCONEL® 600 |

-150 |

-100 |

2,000 |

1,090 |

INC 600 |

| INCONEL® 625 |

-150 |

-100 |

2,000 |

1,090 |

INC 625 |

| INCONEL® X750 |

-150 |

-100 |

2,000 |

1,090 |

INX |

| MONEL® 400 |

-200 |

-130 |

1,500 |

820 |

MON |

| Nickel 200 |

-320 |

-195 |

1,400 |

760 |

NI |

| Titanium |

-320 |

-195 |

2,000 |

1,090 |

TI |

Material used for filler strips are as following for spiral wound gaskets.

| Material |

Minimum |

Maximum |

Abbreviation |

| °F |

°C |

°F |

°C |

| Ceramic |

-350 |

-212 |

2,000 |

1,090 |

CER |

| Flexible Graphite |

-350 |

-212 |

950 |

510 |

F.G. |

| PTFE |

-400 |

-240 |

500 |

260 |

PTFE |

| Verdicarb (Mica Graphite) |

-350 |

-212 |

350 |

175 |

VC |

|