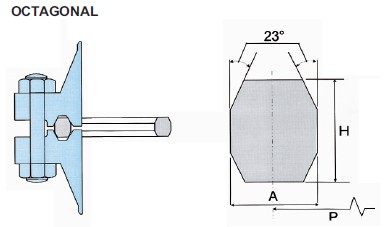

八角型金属环垫

Octagonal ring type joint gaskets are primarily used in the Oil, Gas and Petrochemical industries to seal flanged connections subject to high pressure and temperatures, and form a metal to metal seal with the flanges.

The Octagonal ring type joint gaskets fully comply with the ASME B16.20 standard and the API spec 6A requirements (where applicable). All gaskets complying to API Standard 6A are marked with API Monogram Licence No as per API-6A (PSL4). The Octagonal ring type joint gaskets meet the rigid quality requirements for Ring Joint Gaskets set by the American Petroleum Institute (API).

Octagonal ring type joint gaskets Materials includes Soft Iron, Low Carbon Steel, F5 Alloy Steel, 410 Alloy Steel, SS304, SS304L, SS316, SS316L, SS347, SS321, Nickel Alloy 625 & 825, Duplex, Super Duplex, Monel & other materials available.

Type: Oval Octogonal RX BX

| Material |

Identification |

Max, Hard |

Temperature(° C) |

| SoftIron |

D |

90 |

540 |

| Low Carbon Steel |

S |

120 |

540 |

| 5Cr0.5Mo |

A182-F5 |

130 |

650 |

| SS304 |

SS304 |

160 |

800 |

| SS316 |

SS316 |

160 |

800 |

| SS316L |

SS316L |

150 |

800 |

Please see the dimensions chart of Octagonal ring type joint gaskets in the following:

| PRESSURE CLASSES |

| ASME B16.5 |

API 6B |

ASME B16.47 Series A |

| 150# |

300# – 600# |

900# |

1500# |

2500# |

720# - 960# (1) |

2000# |

3000# |

5000# |

10000# |

150# |

300# - 600# |

900# |

| ½” |

- |

R-11 |

R-12 |

R-12 |

R-13 |

- |

- |

- |

- |

- |

- |

- |

- |

| ¾” |

- |

R-13 |

R-14 |

R-14 |

R-16 |

- |

- |

- |

- |

- |

- |

- |

- |

| 1” |

R-15 |

R-16 |

R-16 |

R-16 |

R-18 |

R-16 |

R-16 |

R-16 |

R-16 |

R-82 |

- |

- |

- |

| 1 ¼” |

R-17 |

R-18 |

R-18 |

R-18 |

R-21 |

R-18 |

R-18 |

R-18 |

R-18 |

- |

- |

- |

- |

| 1 ½” |

R-19 |

R-20 |

R-20 |

R-20 |

R-23 |

R-20 |

R-20 |

R-20 |

R-20 |

R-84 |

- |

- |

- |

| 2” |

R-22 |

R-23 |

R-24 |

R-24 |

R-26 |

R-23 |

R-23 |

R-23 |

R-24 |

R-85 |

- |

- |

- |

| 2 ½” |

R-25 |

R-26 |

R-27 |

R-27 |

R-28 |

R-26 |

R-26 |

R-26 |

R-27 |

R-86 |

- |

- |

- |

| 3” |

R-29 |

R-31 |

R-31 |

R-35 |

R-32 |

R-31 |

R-31 |

R-31 |

R-35 |

R-87 |

- |

- |

- |

| 3 ½” |

R-33 |

R-34 |

- |

- |

- |

- |

- |

- |

R-37 |

R-89 |

- |

- |

- |

| 4” |

R-36 |

R-37 |

R-37 |

R-39 |

R-38 |

R-37 |

R-37 |

R-37 |

R-39 |

R-88 |

- |

- |

- |

| 5” |

R-40 |

R-41 |

R-41 |

R-44 |

R-42 |

R-41 |

R-41 |

R-41 |

R-44 |

R-90 |

- |

- |

- |

| 6” |

R-43 |

R-45 |

R-45 |

R-46 |

R-47 |

R-45 |

R-45 |

R-45 |

R-46 |

- |

- |

- |

- |

| 8” |

R-48 |

R-49 |

R-49 |

R-50 |

R-51 |

R-49 |

R-49 |

R-49 |

R-50 |

- |

- |

- |

- |

| 10” |

R-52 |

R-53 |

R-53 |

R-54 |

R-55 |

R-53 |

R-53 |

R-53 |

R-54 |

R-91 |

- |

- |

- |

| 12” |

R-56 |

R-57 |

R-57 |

R-58 |

R-60 |

R-57 |

R-57 |

R-57 |

- |

- |

- |

R-57 |

R-57 |

| 14” |

R-59 |

R-61 |

R-62 |

R-63 |

- |

R-61 |

R-61 |

R-61 |

- |

- |

- |

R-61 |

R-62 |

| 16” |

R-64 |

R-65 |

R-66 |

R-67 |

- |

R-65 |

R-65 |

R-65 |

- |

- |

- |

R-65 |

R-66 |

| 18” |

R-68 |

R-69 |

R-70 |

R-71 |

- |

R-69 |

R-69 |

R-69 |

- |

- |

- |

R-69 |

R-70 |

| 20” |

R-72 |

R-73 |

R-74 |

R-75 |

- |

R-73 |

R-73 |

R-73 |

- |

- |

- |

R-73 |

R-74 |

| 22” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-80 |

R-81 |

- |

| 24” |

R-76 |

R-77 |

R-78 |

R-79 |

- |

- |

- |

- |

- |

- |

- |

R-77 |

R-78 |

| 26” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-93 |

R-100 |

| 28” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-94 |

R-101 |

| 30” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-95 |

R-102 |

| 32” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-96 |

R-103 |

| 34” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-97 |

R-104 |

| 36” |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

R-98 |

R-105 |

Notes: (1) - Class 720, 960, 10000 and 2900 flanges to API 6B are obselete. Data is for informational purposes only.

(2) - R-30 is for lapped joint only. |

|